Industrial weighing systems

Accuracy: 1 – 2%

The RW222 pipe scale is a device for measuring the flow and weighing out specific portions of bulk materials directly in vertical pipes for transporting such materials as sand, grain, granules.

It is built as a compact and modular device, which makes it ideal for use in both simple under-tank installations and extended measurement sets (measurement networks).

The RW222 scale is an IoT (Internet of Things) device, with functions for communicating with the Internet via wireless network or Ethernet. Such a solution makes it possible to perform remote maintenance, i.e. diagnostics, collection of historical data, realization of remote access – calibration, zeroing, etc.

-

The RW222 meets all user requirements in a way not previously possible:

-

requires minimal space for installation,

-

provides current and historical measurement data and device status,

-

is extremely simple to build,

-

careful shaping of the jet stream ensures high accuracy,

-

it does not include an operator panel, all weighing data are transmitted over ETHERNET communication with MODBUS TCP/IP protocol (option on the operator panel),

-

Scale controller based on ESP-32 microcontroller, specially prepared for IoT (Internet of Things) technology.

-

MODBUS TCP/IP (Ethernet)-visible on the computer system:

-

instantaneous flow,

-

total since the last deletion,

-

unassessable total,

-

coefficient of current weighted material,

-

alerts,

-

calibration,

-

admin password.

Accuracy class: 0,2 / 0,5 / 1

-

Scale functions:

-

determination of instantaneous and average flow,

-

summing weighted portions,

-

dispensing a certain amount of material,

-

automatic tare and zeroing of the weight for each cycle,

-

adapted for cooperation with the master system,

-

communication via MODBUS TCP (ETHERNET), PROFIBUS or PROFINET interface

The scale is designed for automatic weighing of the product when transferring bulk, dusty and granular materials.

-

Scale functions:

-

determination of the sum of the weighted product,

-

flow determination,

-

communication via MODBUS TCP (ETHERNET), PROFIBUS or PROFINET interface.

-

Device description

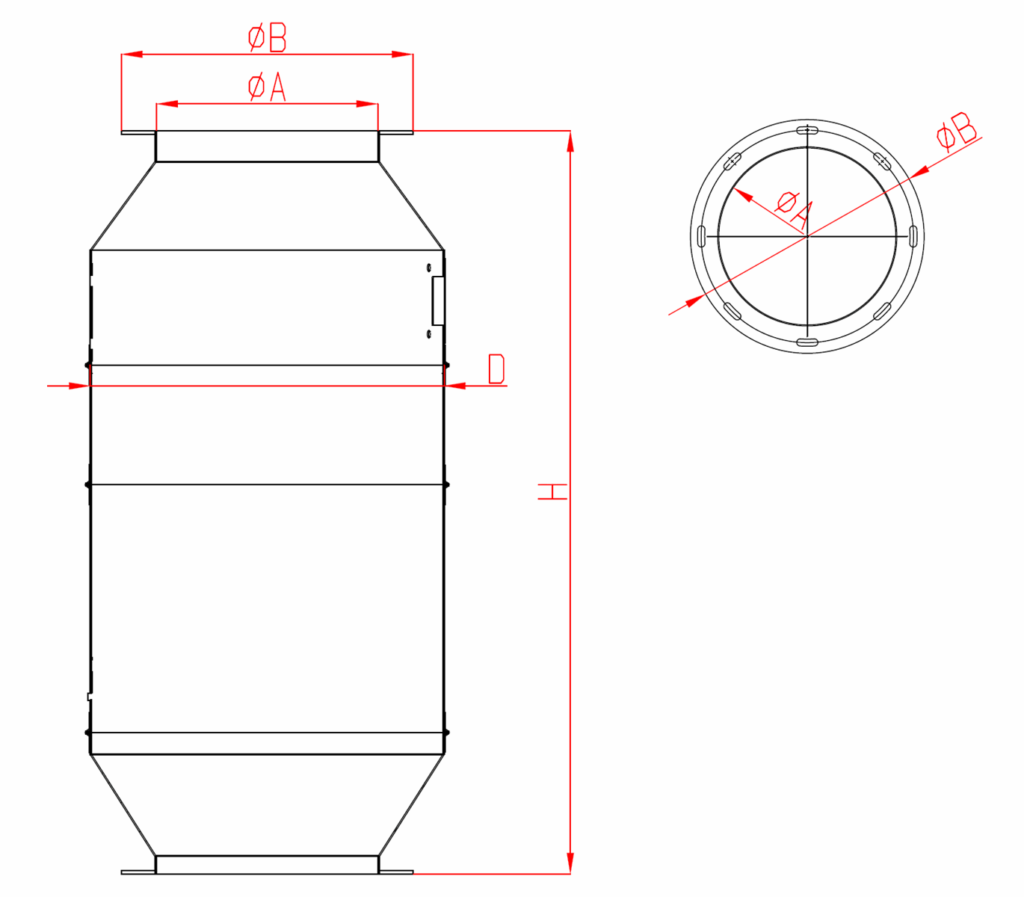

Technical parameters of the scale WP-1 :

-

accuracy class 1 – 3%

-

flow do 50t/h

-

working temperature of the scale -5°C do +40°C

-

dimensions H x A x B 500 x 450 x 300

The WP-1 flow scale is very popular in all enterprises where loose, dusty or granular products are processed, which is why it is supplied to mills, feed factories and many other enterprises. The main element of the flow scale is the measuring plate on which the product is weighed out during the flow through the scale.

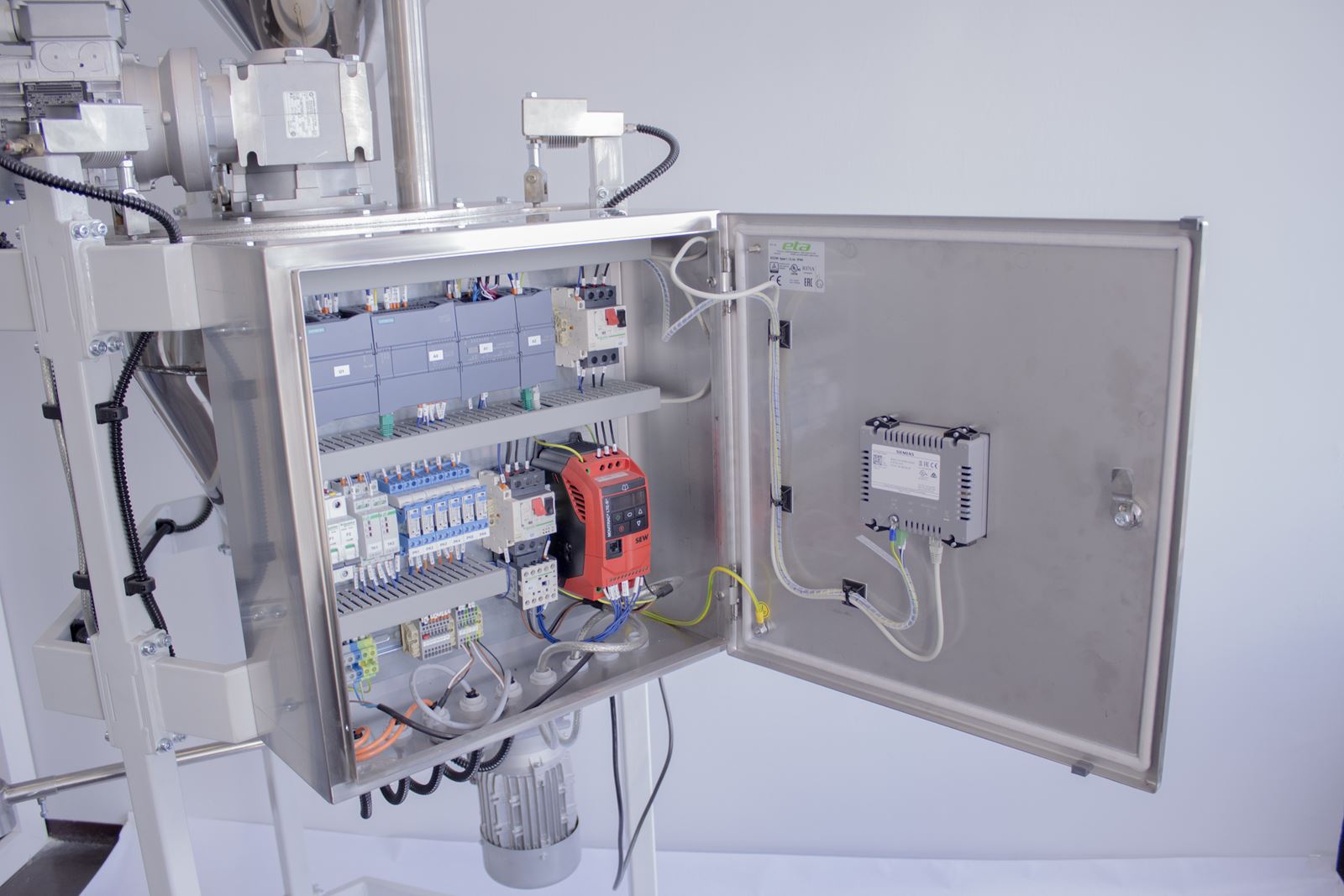

The devices are designed for precise batching by weight of bulk materials. The batching tank of the dispenser is equipped with an agitator, which prevents suspension and clumping of the dispensed products. It is possible to combine several dispensers with different components into one continuous mixer.

Device description

-

Basic functions:

-

capacity control in [kg/h],

-

kommunication via MODBUS TCP (ETHERNET), PROFIBUS or PROFINET interface,

-

devices in plain steel or stainless steel versions.

Micro doser – Screw feerder is one of the newest devices in our range, and has already become very popular due to its properties. The dispenser measures and dispenses micro-additives, dyes and vitamins and trace elements with extreme accuracy. It is most popular in mills that add special microelements to flour, and thanks to our device they can easily maintain a constant level of added micro-additives and thus can always offer their customers the highest quality.

This is an electronic flow regulator used to regulate the weight of the flowing bulk product. This regulator also serves as a percentage controller in the circuit of many such devices.

-

Device description

Technical parameters of the flow balancer RP-1 :

-

capacity up to 30 t/h

-

stabilization error 2 – 3%

-

power supply 230 VAC

-

operating temperature -5°C to +40°C

-

dimensions H x A x B 500 x 450 x 300